You are here:

- Home

- Product

- Food and pharmaceutical industries

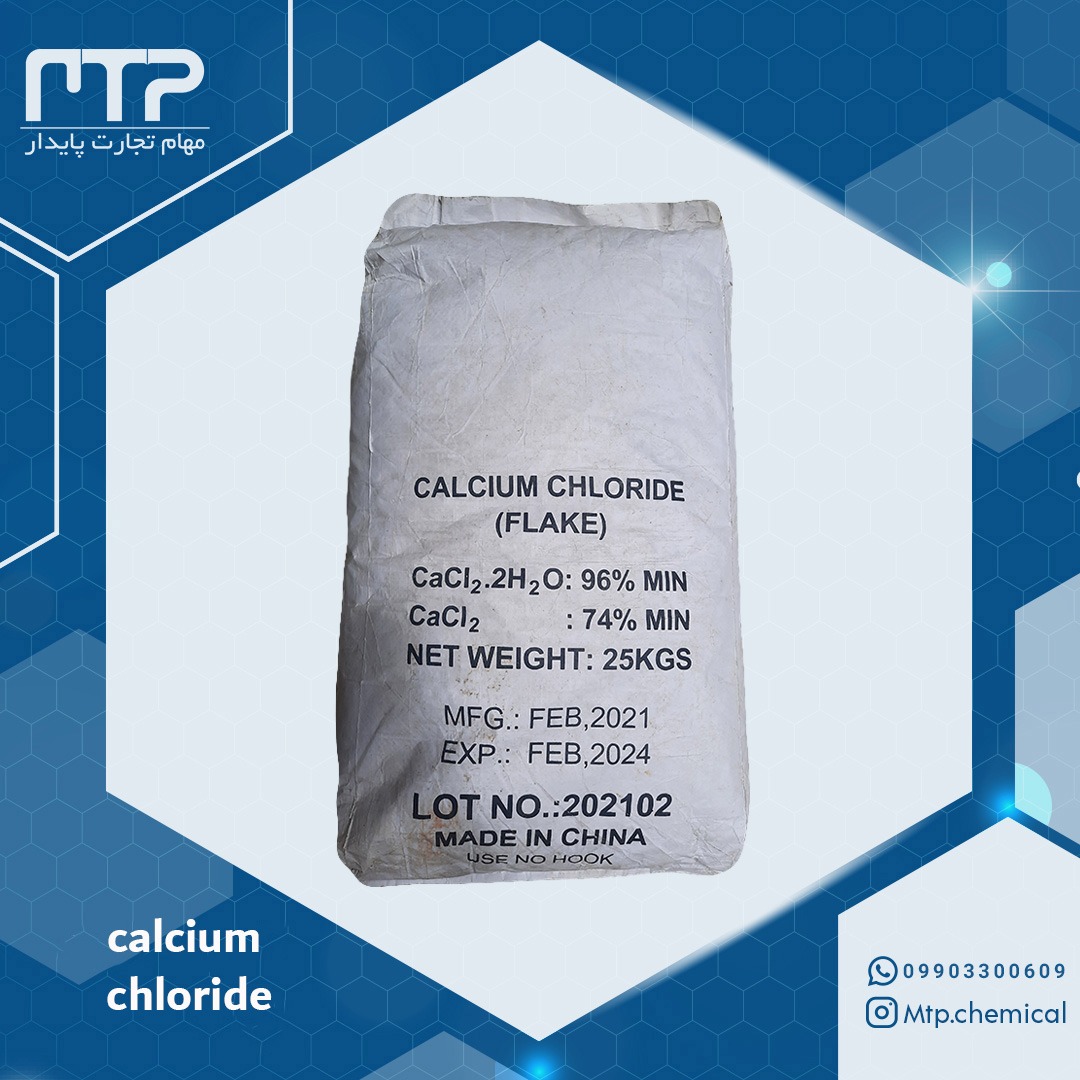

- calcium chloride (flake)

Product code: N/A

calcium chloride (flake)

This substance is one of the most widely used salts in both edible and industrial grades for the production of edible substances and chemical fertilizers. Next, physical and chemical properties, applications, reactions (with water), role in making food such as cheese, in agriculture as fertilizer, etc. Been paid.To buy and know the price of this product, contact the telephone numbers of Maham Tejarat Pagdar Company.

01732220442-01732255539

02186053798

09903300609

Description

Characteristics

No Reviews

Description

what is calcium chloride

(flake) calcium chloride, or CaCl2, is a mineral compound that is highly soluble in water. Calcium chloride is typically found as a white crystalline solid at room temperature, in the form of powder or flakes with purities of 77% or 94%. It is an important salt with numerous household and industrial applications. Calcium chloride is usually a hydrated solid with the general formula CaCl2 (H2O) x, where x can be 0, 1, 2, 4, or 6. These compounds are primarily used for de-icing and dust control purposes. It is a odorless and salty-tasting powder with a melting point of 782 degrees Celsius and a boiling point above 1600 degrees Celsius. Calcium chloride is used in swimming pools and water treatment facilities and also serves as a drying agent in laboratories and factories. It also finds applications in metallurgical industries, oil well drilling, rubber production, paper manufacturing, and dyeing.

What is the use of calcium chloride

Calcium chloride has several uses. One of its advantages in concrete production is that concrete made with calcium chloride has greater resistance to erosion. However, it is more susceptible to sulfate attack, resulting in a decrease in concrete strength by about 10 to 15 percent, and the worst damage caused by this substance is corrosion of reinforcement. Therefore, the use of calcium chloride is only allowed in non-reinforced concrete.

Additionally, calcium chloride is used for snow and ice melting on roads and highways during winter, controlling dust on dirt roads, stabilizing soil in desert areas, chemical industries, oil and gas industries, and as an accelerator in concrete production for the winter season.

Calcium chloride can also be used as a food additive. It is used as a firming agent in canned vegetables such as cabbage, soybeans, beans, or fruit juice. It is also used as an electrolyte in sports drinks and adds a sour taste to food without adding sodium.

In terms of production, calcium metal can be obtained from the electrolysis of calcium chloride mixed with fluoride and potassium chloride. In this method, carbonaceous anodes and iron cathodes are used. On a smaller scale, lime can be reduced with aluminum metal in a vacuum chamber followed by recycling of the calcium metal. Additionally, calcium chloride can be produced either by treating mineral carbonate with hydrochloric acid or as a byproduct in the Solvay process.

In concrete production, calcium chloride plays the role of an accelerator. It is first mixed with water and then added to the sand and cement mixture. This allows for the use of regular cement along with calcium chloride for rapid-setting concrete production.

How to prepare calcium chloride

the following steps can be followed:

1- Take a glass. Wear gloves and put enough limestone in the glass to fill a quarter of the glass.

2- Add approximately 1/4 cup of HCl (hydrochloric acid) to the limestone.

3- When limestone dissolves in HCl, it starts to bubble. Mix the contents of the beaker gently and make sure the reaction is complete. If all the limestone is completely dissolved in it, add some limestone back to the glass.

4- As soon as the solution bubbles stop, filter the material by passing through the filter paper.

5- Heat the second glass containing the calcium chloride solution. Calcium chloride is the solid substance that remains after the evaporation of water.

Buy calcium chloride

Relying on business knowledge and knowledge of the chemical supply market, Maham Tejarat paidar Company has been able to become a trusted supplier of dear manufacturers in a short period of time. And you can get high-quality calcium chloride in various volumes using the supply chain of sustainable trade tasks as soon as possible.

Characteristics

No Reviews

Be the first to review “calcium chloride (flake)” Cancel reply

Reviews

There are no reviews yet.